Fehlersuche: Häufige Probleme

Diamantwerkzeuge werden häufig für die Oberflächenvorbereitung, wie das Schleifen von Beton, sowie zum Schneiden und Entkernen von Beton verwendet. Da es Dutzende von Herstellern und Hunderte von Optionen auf dem Markt gibt, ist es wichtig, dass Sie wissen, was Sie verwenden und wie Sie es am besten einsetzen. Das richtige Diamantwerkzeug für eine bestimmte Aufgabe sorgt für schnellere Ergebnisse und ein besseres Finish. Im Folgenden gehen wir auf einige der häufigsten Fragen zur Fehlerbehebung ein, die wir bei der Betonvorbereitung mit Diamantwerkzeugen erhalten.

Verglasung

Wenn Sie mit der Verglasung nicht vertraut sind, es kann schwer zu erkennen seinaber Ihr Schleifgerät hinterlässt normalerweise Spuren. Nachdem Sie einen Durchgang mit Ihrer handgeführten Betonschleifmaschine gemacht haben, beobachten Sie das Kratzmuster auf der Oberfläche. Wenn die Spuren schwach oder uneinheitlich aussehen, ist möglicherweise Glasur der Übeltäter.

Glasbildung tritt auf, wenn metallgebundene Diamantwerkzeuge nicht richtig auf die Härte des Betons abgestimmt sind. Anstatt dass die Diamanten freiliegen und effizient schneiden, bleiben sie in der Bindung gefangen. Die Folge? Das Werkzeug wird langsamer oder hört in manchen Fällen sogar ganz auf zu schneiden.

Die Anpassung der Werkzeuge an die Betonhärte ist der einfachste Weg, um Verglasungen zu vermeiden und eine optimale Leistung Ihrer Schleifmaschine zu gewährleisten.

Mögliche Lösungen:

- Testen Sie die Härte Ihres Betons.

- Weicher Beton sollte mit hart gebundenen Diamanten und harter Beton mit weich gebundenen Diamanten gepaart werden. Wenn Ihre Diamanten glasig sind, müssen Sie in der Regel auf eine mittlere oder weiche Bindung zurückgreifen.

- Abrichten oder Schärfen des Werkzeugs mit einem weichen Betonklotz oder einer Schleifscheibe (falls weiterhin Verglasungen auftreten, wechseln Sie zu einer weicheren Bindung)

- Verringern Sie Ihre Arbeitsgeschwindigkeit. Wenn die Schleifmaschine mit variabler Geschwindigkeit arbeitet, verlangsamen Sie sie!

Übermäßiger Segmentverschleiß

Wenn sich Ihre metallgebundenen Diamantwerkzeuge zu schnell abnutzen, ist das ein Zeichen dafür, dass Sie die Werkzeuge nicht auf die Anwendung und die Maschine abgestimmt haben. Das richtige Diamantwerkzeug hängt von der Betonhärte, den zuvor aufgetragenen Beschichtungen, dem Maschinengewicht, der Drehzahl des Werkzeugs und anderen Bedingungen ab. Übermäßiger Verschleiß verkürzt die Lebensdauer des Werkzeugs, insbesondere bei stark abrasiven Materialien, und wird teuer, wenn Sie das Werkzeug verbrauchen.

Mögliche Lösungen:

- Prüfen Sie den Verbund: Passen Sie den Verbund an die Härte des Betons an (weicher Verbund = harter Beton usw.)

- Reduzieren Sie die Schleifgeschwindigkeit: Verlangsamen Sie Ihren Schleifer, um zu sehen, ob Sie mit den Werkzeugen andere Ergebnisse erzielen.

- Stellen Sie Fragen: Wurde der Beton zuvor verdichtet? Chemische Zusatzstoffe verändern die Vorgehensweise bei der Oberflächenvorbereitung.

- Haben Sie die richtige Maschine: Stimmen Sie das Gewicht des Schleifkopfes auf die Art des Segments ab. Die Form und Höhe der Segmente beeinflusst die Abnutzung des Diamanten.

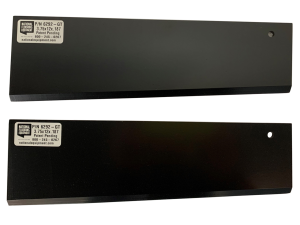

- Der Umfang der Oberfläche mit einem Einstab- oder Doppelstab-Diamantwerkzeug verändert die Oberfläche, die mit dem Boden in Berührung kommt

Haben Sie den richtigen Segmentstil?

Die optimale Nutzung Ihrer Schleifeinrichtung beginnt mit einem Schlüsselfaktor: der Abstimmung des Gewichts des Schleifkopfes Ihrer Maschine auf das Design des Diamantsegments.

Form und Höhe des Segments spielen eine große Rolle dabei, wie gleichmäßig das Werkzeug verschleißt, was sich direkt auf Leistung und Lebensdauer auswirkt. Die Wahl der richtigen Paarung schützt nicht nur Ihre Diamanten, sondern spart auch Zeit und Geld auf der Baustelle.

Ein weiteres Detail, das zu berücksichtigen ist, ist die Oberfläche der den Diamantwerkzeugen. Ein einzelnes Stangensegment hat weniger Kontaktfläche mit dem Boden, was den Druck auf die Diamanten erhöht und den Materialabtrag beschleunigt. Bei Werkzeugen mit zwei Segmenten wird die Kontaktfläche vergrößert, was zu mehr Kontrolle, gleichmäßigerem Schleifen und längerer Lebensdauer führt.

Kurz gesagt: Gleichen Sie das Kopfgewicht Ihrer Maschine mit dem richtigen Werkzeugdesign aus. Die richtige Kombination führt zu sauberen Ergebnissen, gleichmäßigem Verschleiß und maximaler Rentabilität Ihrer Investition.