Kontrollierte Partikelplatzierung

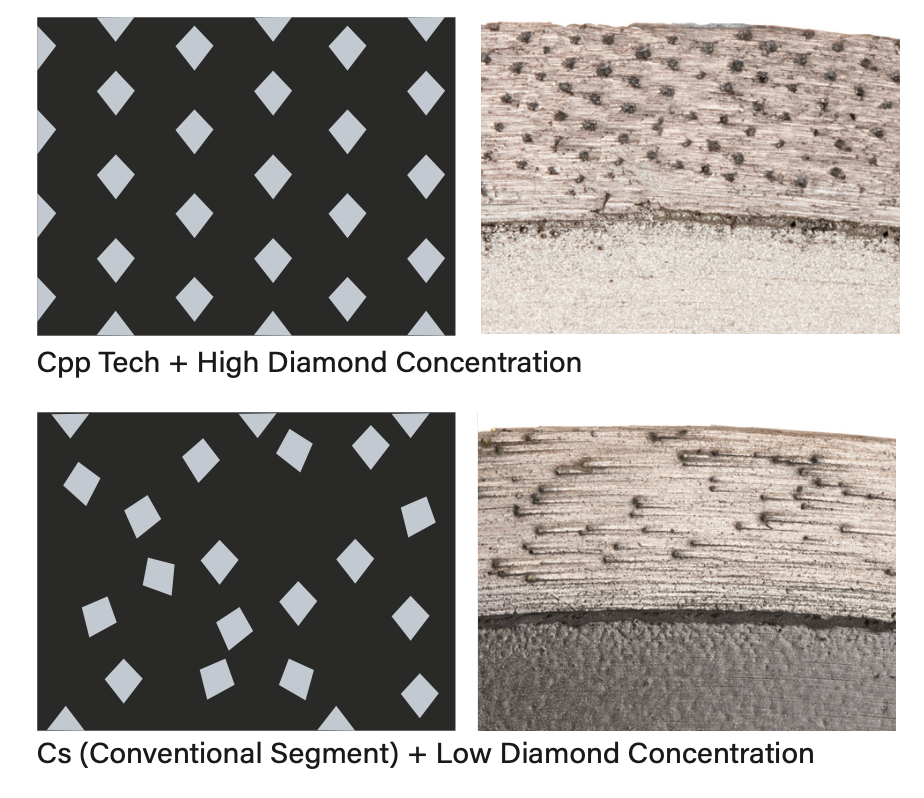

Controlled Particle Placement (CPP) ist eine Methode zur Anordnung von Diamantschleifpartikeln in der Bindung von Schneidsegmenten. Dieses präzise Muster sorgt für eine gleichmäßige Abnutzung der Diamanten während der gesamten Lebensdauer des Segments. Einige Betonsägeblattsegmente sind mit diesem Diamantmuster versehen, andere haben eine natürlichere Anordnung.

Professionelle Schneideunternehmen haben in der Regel eine Vorliebe für die Art der Segmentplatzierung, die sie in jedem ihrer Messer bevorzugen. Abhängig von der Schneidanwendung und dem Hersteller des Werkzeugs ist diese Präzisionsanordnung in vielen Anwendungen zu finden.

CPP-Technologie in Aktion

Die CPP-Schneidtechnologie wird manchmal auch als konfigurierte, kontrollierte oder gemusterte Platzierung bezeichnet und wird in einer Vielzahl von Diamantwerkzeugsegmenten eingesetzt. Viele Hochleistungsbetonsägen und Spezialsägeblätter basieren auf CPP, um harten Beton effektiv zu durchtrennen.

Das Konzept ist einfach: Synthetische Diamanten werden in einem kontrollierten Muster in den Verbund eingebracht. Angeordnet in einer präzisen Formation, wie Soldaten, die im Gänsemarsch marschieren, wirken die Diamanten zusammen, um ein konsistentes, einheitliches Kratzmuster zu erzeugen. Dieses Design finden Sie bei den Wandsägeblättern von Syntec und bei ausgewählten Sägeblättern für den frühen Einsatz.

Das Besondere an CPP ist die computergestützte Platzierung der Diamanten, die Genauigkeit auf mikroskopischer Ebene gewährleistet. Und das Ergebnis? Schneller Schnittgeschwindigkeiten und eine längere Lebensdauer der Klingen - ein klarer Vorteil für Bauunternehmer, die sowohl Leistung als auch Haltbarkeit verlangen.

Um mehr zu erfahren über Diamantsegmente und Schneiden, wenden Sie sich noch heute an Ihren Experten für Oberflächenvorbereitung vor Ort.